Today however it is generally accepted that lip seals have limitations, but due to inexpensive initial cost they continue to be widely applied. Rubbing, lip seals can’t fully protect the bearing from moisture or particle ingress, which ultimately results in bearing failure.

This surface contact often results in costly damage to the shaft itself (left). They rely on surface contact between the seal lip and the shaft to form the seal. Historically the most common way of protecting bearings was The laws of physics are at work here.The image on the right Illustrates the consequences of this contamination. Temperatures cause pressures to go up, while decreasing temperatures cause pressures to decrease. With increasing temperatures, the vapors floating above the liquid oil level will expand with decreasing temperatures the vapors will contract. Nighttime, and temperatures differ when operating versus non-operating. Also, bearing housings undergo temperature shifts from daytime to

Way into bearing housings through openings where equipment shafts protrude through bearing housings, or at vents and breathers provided somewhere on the oil-lubricated assembly. Research and follow-up analysis by bearing producers and users has established lubricant contamination as the predominant failure cause (see chart above).

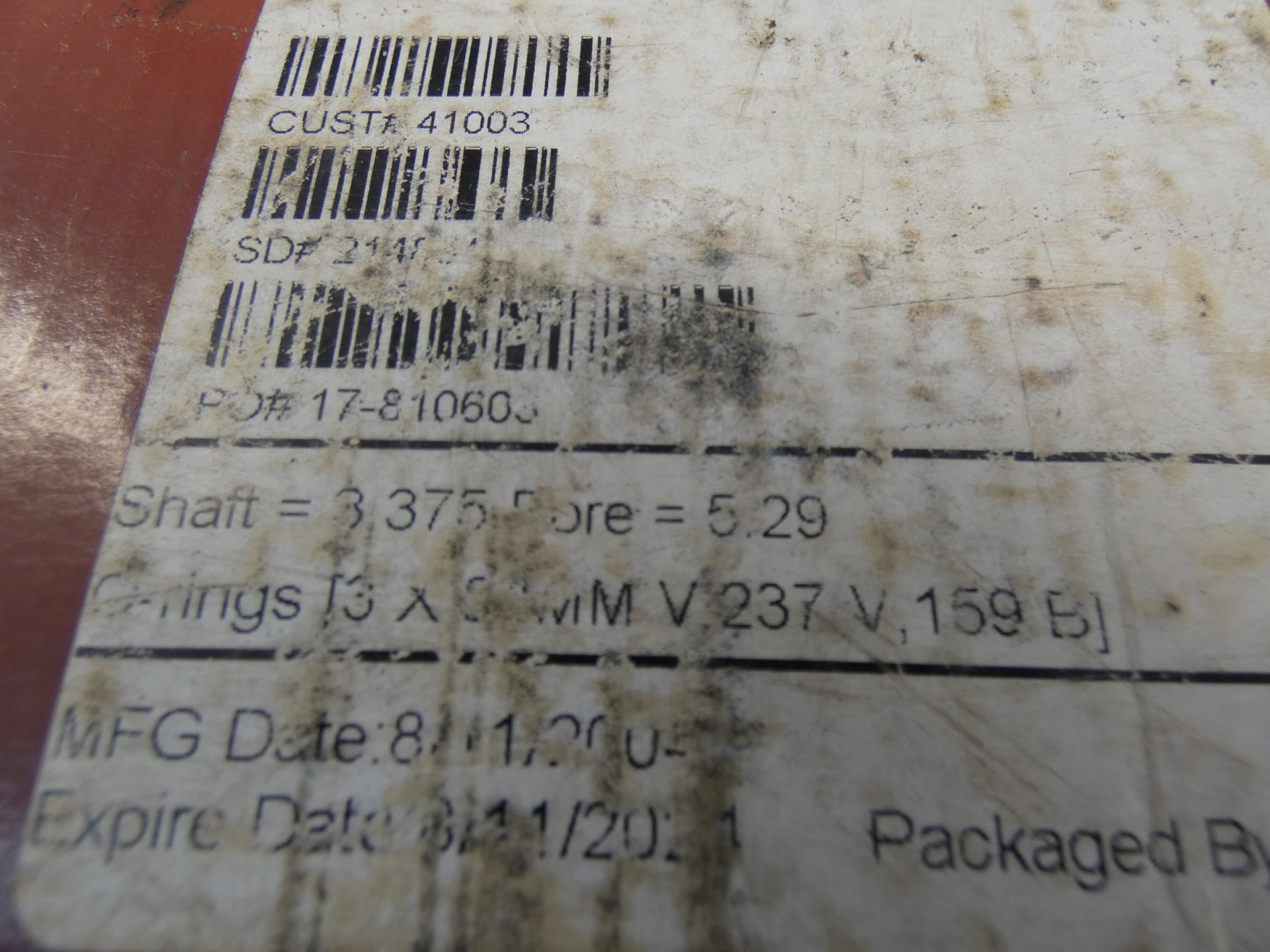

It has long been recognized that as many as 91% of all the rolling element bearings installed in the world’s machinery fall short of reaching the manufacturer’s calculatedĬauses of Bearing Failure Lubricant contamination Bloch has written 18 books and over 480 technical papers on practical machine management, reliability engineering, oil mist To learn more about INPRO/SEAL, please visit article was written by Heinz P Bloch, mechanical engineering authority, consultant and author. Inpro/Seal products are custom engineered to fit exact equipment and environment requirements for optimized performance.ĪRO is headquartered in Rock Island, Illinois. Their distinct product line offers permanent solutions to many of the costly maintenance problems that disrupt normal production. Our innovative technology increases equipment reliability and provides real cost savings by improving mean time between repair (MTBR). Inpro/ Seal is a world leader in the design and manufacture of permanent bearing protection and complete shaft sealing solutions for multiple industries. Tencarva also designs and fabricates process systems – pump packages, electrical control system automation panels – and manufactures the Uniguard Machine Guard product. Tencarva offers over 140 manufacturer brands and is an authorized service center for many, including ITT Goulds Pumps, SEEPEX, Gorman Rupp, ARO, and other premier product lines. Since 1978, Tencarva has provided process equipment to the industrial and municipal markets in Arkansas, Florida, Georgia, Mississippi, North Carolina, South Carolina, Tennessee and Virginia. Triad Business Journal recently designated Tencarva Machinery Company as a Fast 50 private company, ranking Tencarva as the 35 th fastest-growing business in the NC Triad in 2019. Inpro/Seal is a world leader in the design and manufacture of permanent bearing protection and complete shaft sealing solutions for multiple industries. As an authorized INPRO/SEAL® distributor, Tencarva Machinery Company will sell and service and provide all INPRO/SEAL® products including bearing isolators and shaft grounding solutions. Tencarva Machinery Company now offers INPRO/SEAL® products in Arkansas, Florida, Georgia, Mississippi, North Carolina, South Carolina, Tennessee and Virginia. Tencarva Machinery Company Named authorized distributor for INPRO/SEAL Custom Pressure Booster Systems Packages.

0 kommentar(er)

0 kommentar(er)